SignTorch

Artist

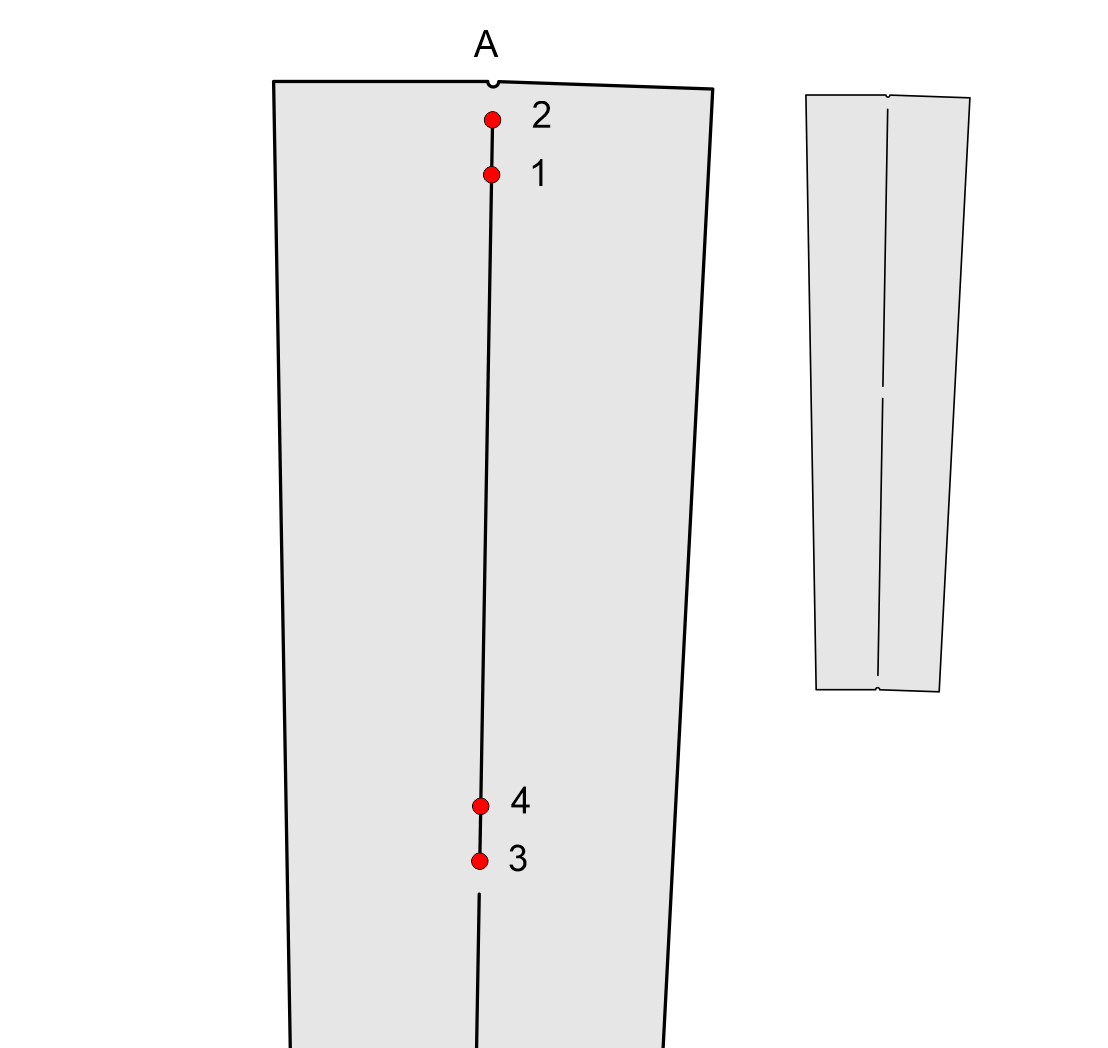

When I plasma cut a part with bend lines, I put a divot on the edge of the part (A), and I pierce and end the bend line cut(s) away from the end of the bend line, so I would pierce at point 1, and cut to point 2 then 3 then end at point 4. That way, each end of each bend line is consistent and consistent with the edge bend points, so all have similar geometry when cut. Without the divot, the edge will bend differently (larger radius) than at the bend line(s). If the pierce point is at one end of the bend line, and the cut end point is at the other end, then each end of the bend line cut will have different width and will not bend the same. If you are trying to bend a right angle without divots and cuts ending away from the end of the bend line as described, then each end of the bend will bend at different radii and the two bent sides will not be in perpendicular planes. No matter what the bend angle is, if the bend radius is different at each end of the bend, then neither side will be perpendicular to that bend angle.