SignTorch

Artist

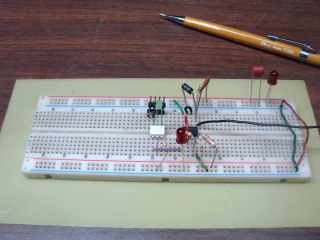

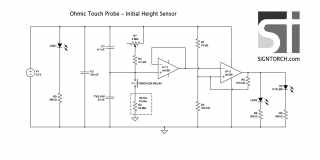

Ok, made some progress on the touch probe.

Not ready for production. Still must develop a fail-safe mechanism before it can be used and really tested.

It's very simple and very sensitive. It's almost too good to be true, so until I can test it right, I'm not sure I believe it can be that simple and that effective without some sort of problem, so stay tuned.

It detects through heavy rust, paper, and skin (if grounded). It can touch off on a bowed piece of .005" brass shim stock without flexing it at all.

Not ready for production. Still must develop a fail-safe mechanism before it can be used and really tested.

It's very simple and very sensitive. It's almost too good to be true, so until I can test it right, I'm not sure I believe it can be that simple and that effective without some sort of problem, so stay tuned.

It detects through heavy rust, paper, and skin (if grounded). It can touch off on a bowed piece of .005" brass shim stock without flexing it at all.